Forging Capabilities for Strong and Reliable Industrial Components

The modern manufacturing landscape demands parts that can endure extreme stress, temperature, and repetitive load cycles. Forging has emerged as a cornerstone process for meeting these expectations, enabling manufacturers to produce components with superior mechanical integrity. When designed and executed correctly, Forging enhances grain flow, reduces internal defects, and delivers unmatched reliability. Industries ranging from automotive to energy rely on Forging to ensure safety, consistency, and long service life in critical applications.

Understanding the Foundation of Component Strength

At its core, the process reshapes metal under compressive forces to align its internal structure with the geometry of the part. This alignment improves toughness and fatigue resistance compared to cast or machined alternatives. The result is a component capable of handling higher loads without failure. By applying Forging under controlled conditions, manufacturers can achieve uniform properties throughout the part, minimizing weak points that could compromise performance.

Advanced Process Control and Material Selection

Precision begins with choosing the right alloy and carefully controlling temperature, pressure, and deformation rates. While the term Forging is often associated with heavy industry, modern facilities use sophisticated simulation and monitoring systems to optimize every step. These technologies ensure repeatability across batches and allow fine-tuning for specific performance targets. High-quality steels, aluminum alloys, and specialty metals benefit from this approach, producing parts that meet strict dimensional and metallurgical requirements.

Design Integration for Performance and Efficiency

Strong components are not just the result of processing; they are also the product of smart design. Engineers collaborate closely with manufacturing teams to integrate geometry that supports load paths and reduces unnecessary material. Through early design involvement, the process supports near-net shapes, lowering machining time and material waste. This integration shortens lead times, reduces costs, and improves sustainability without sacrificing strength or reliability.

Quality Assurance and Testing Protocols

Reliability in industrial components depends on rigorous inspection and testing. Non-destructive evaluation methods such as ultrasonic testing, magnetic particle inspection, and dimensional verification help confirm internal soundness and surface integrity. Statistical process control further ensures consistency from one production run to the next. By embedding quality checks throughout manufacturing, suppliers deliver components that consistently meet or exceed industry standards.

Applications Across Critical Industries

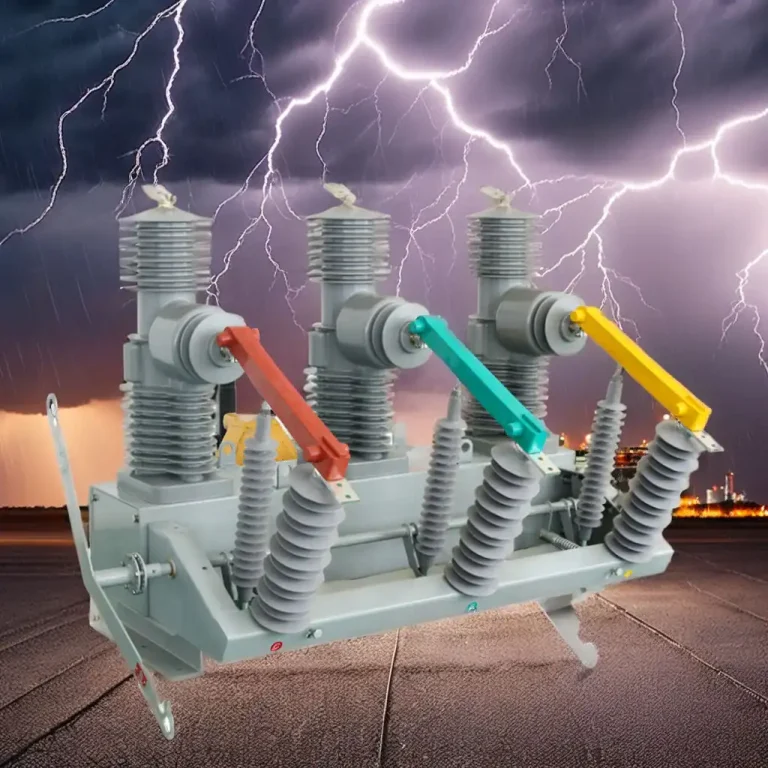

From crankshafts and gears in vehicles to valves and flanges in oil and gas systems, high-integrity components are essential to operational safety. Power generation, aerospace, construction, and heavy equipment sectors all depend on parts engineered for durability. The ability to customize alloys and shapes makes the process adaptable to diverse environments, including corrosive, high-pressure, and high-temperature conditions.

Building Long-Term Value Through Expertise

Choosing a capable manufacturing partner is as important as the process itself. Experienced providers invest in skilled personnel, modern equipment, and continuous improvement programs. Companies like Leierwo focus on delivering consistent performance by combining technical know-how with customer-centric collaboration. This commitment translates into components that reduce downtime, extend service intervals, and support long-term operational goals.

FAQs

What makes industrial components more reliable than alternatives?

They benefit from a refined internal structure that improves strength, fatigue life, and resistance to impact compared to parts made by casting or extensive machining.

How does process control affect component quality?

Tight control over temperature, pressure, and deformation ensures uniform properties, dimensional accuracy, and repeatable results across production batches.

Can this manufacturing approach support custom designs?

Yes, it works well with tailored geometries and materials, allowing engineers to optimize parts for specific load and environmental conditions.

Which industries gain the most from these components?

Automotive, energy, aerospace, construction, and heavy machinery sectors rely heavily on high-strength, long-life parts for safe and efficient operation.

How does Leierwo support quality and consistency?

By combining advanced equipment, skilled teams, and comprehensive inspection practices, Leierwo delivers components that meet demanding industrial standards.